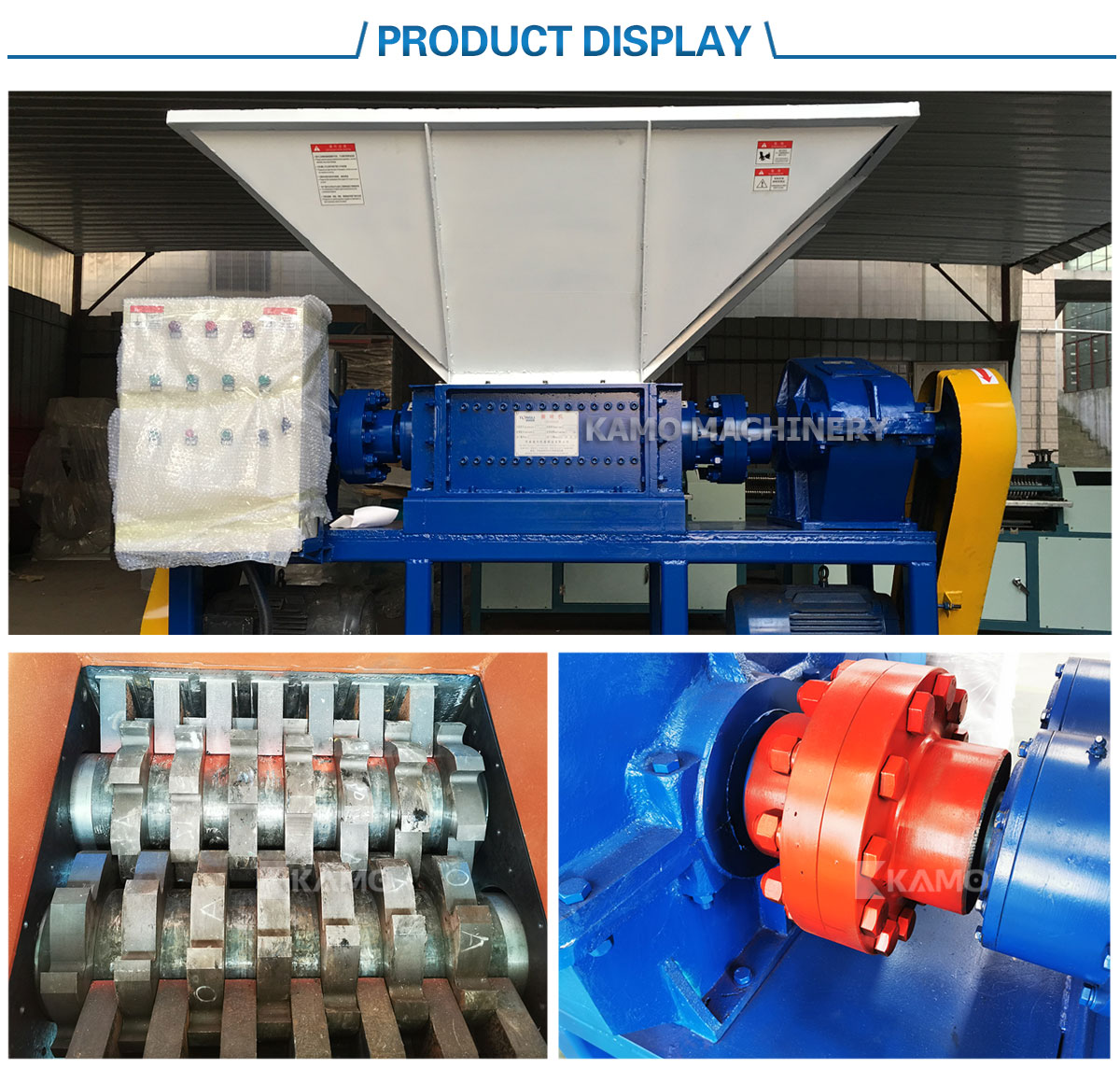

This series double shaft shredder use micro-computer(PC) automatic control. Equipped with start, stop, reversion and overload automatic reverse function. Also having low speed, high torque, low noise and others features.

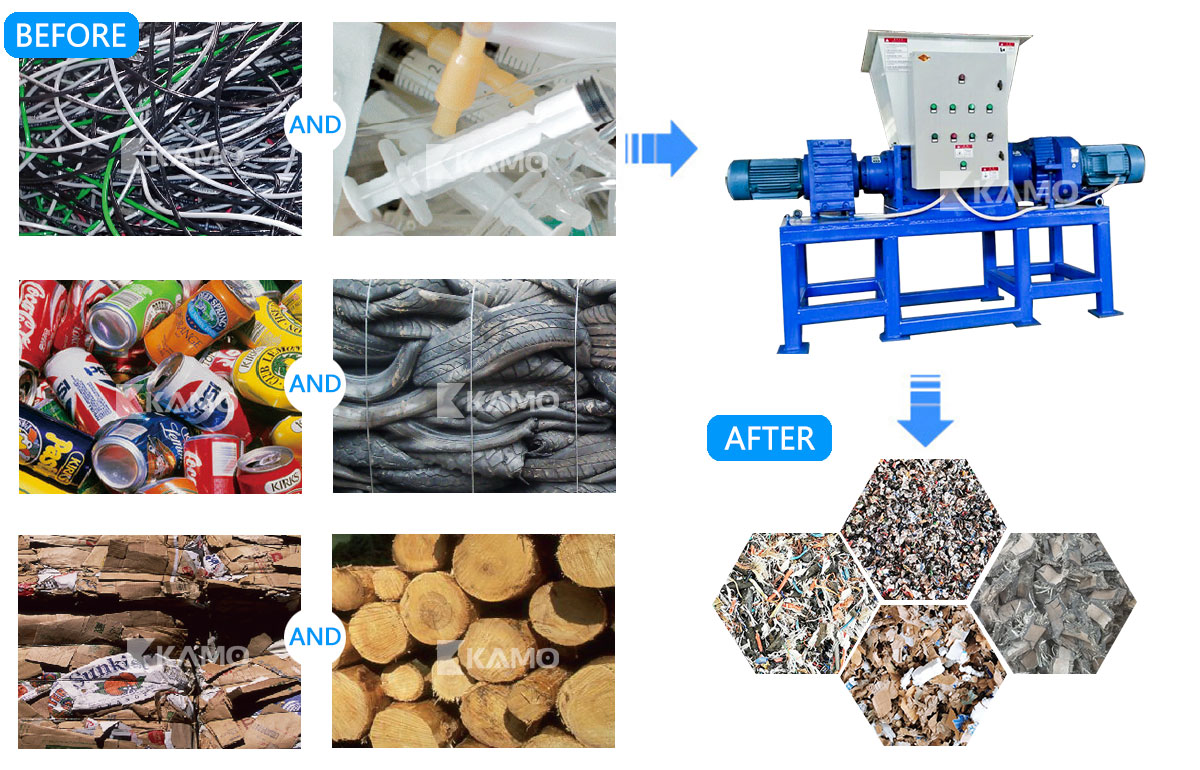

APPLICATION

It is suitable for thick and hard materials, such as: Computer hard drive, small engineering plastic, home appliance, plastic head material etc.

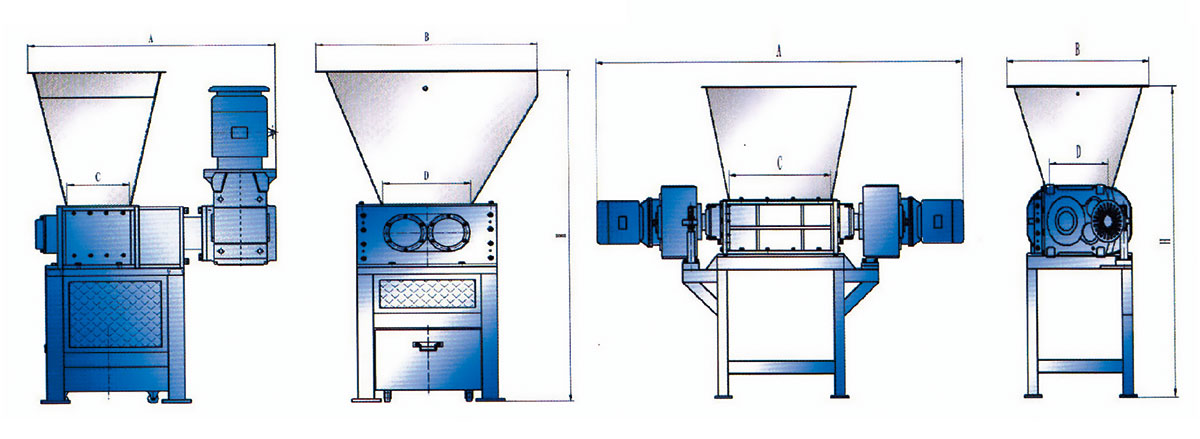

TECHNICAL PARAMETERS

| Model | TL2130 | TL2140 | TL2160 | TL2180 |

| A(mm) | 1210 | 1310 | 2730 | 2930 |

| B(mm) | 1080 | 1080 | 1190 | 1190 |

| C(mm) | 300 | 400 | 600 | 800 |

| D(mm) | 430 | 430 | 510 | 510 |

| H(mm) | 1840 | 1840 | 1930 | 1930 |

| Blade turning diameter | φ284 | φ284 | φ284 | φ284 |

| Main shaft speed(r/min) | 17 | 17 | 15 | 15 |

| Rotor blade quantity(pcs) | 15 | 20 | 30 | 40 |

| Blade thickness | 20 | 20 | 20 | 20 |

| Machine power | 7.5 | 7.5 | 5.5+5.5 | 7.5+7.5 |

Features

1. The main body of the crusher's main equipment adopts high-quality steel plate welding to eliminate stress treatment and overall machining to ensure the stability of the equipment under long-term heavy load.

2. The bearing/sealed bearing seat adopts a patented split type, which can quickly remove the moving knife, fixed knife, bearing and other components. It is easy to maintain and replace the knife. The unique sealing structure effectively blocks the contact of broken objects and grease, and also handles liquid materials. Can protect bearings and gears.

3. The moving knife/fixed knife moving knife materials are made of special alloy tool steel forged blanks, precision machining, multiple heat treatments and low temperature freezing heat treatment technologies. The overall toughness and hardness can be repaired repeatedly to ensure cutting performance and service life. The fixed knife adopts the patent hook type installation, which optimizes the tool replacement function and makes the tool maintenance and replacement more efficient.

4. The cutter shaft is made of high-strength and heavy-load special steel, which is more reasonably matched with the cutter to provide powerful power for cutting.

Note

1.The standard thickness of rotor blade is 20mm, also available in 15mm, user can choose blade based on final output size after crushing.

2.Rotor blade is single claw blade, if need double claw or multiple claw, please contact with our sales department, single claw blade is suitable for relatively hard material, double and multiple claw is for relatively soft material, but with high efficiency.