The PCL1000 vertical crusher is a multifunctional crushing device. The crushing rotor adopts a vertical shaft design. The materials are crushed in multiple stages from the inlet to the outlet to achieve the purpose of crushing and detaching. Material classification and recycling. The equipment covers a small area and has a large difference energy. It has the characteristics of fine crushing for material processing, and the processing capacity is 10-30t/h. This equipment is suitable for the crushing and sorting operation of small materials, and can strip the metal and plastic to facilitate the smooth operation of the subsequent sorting process.

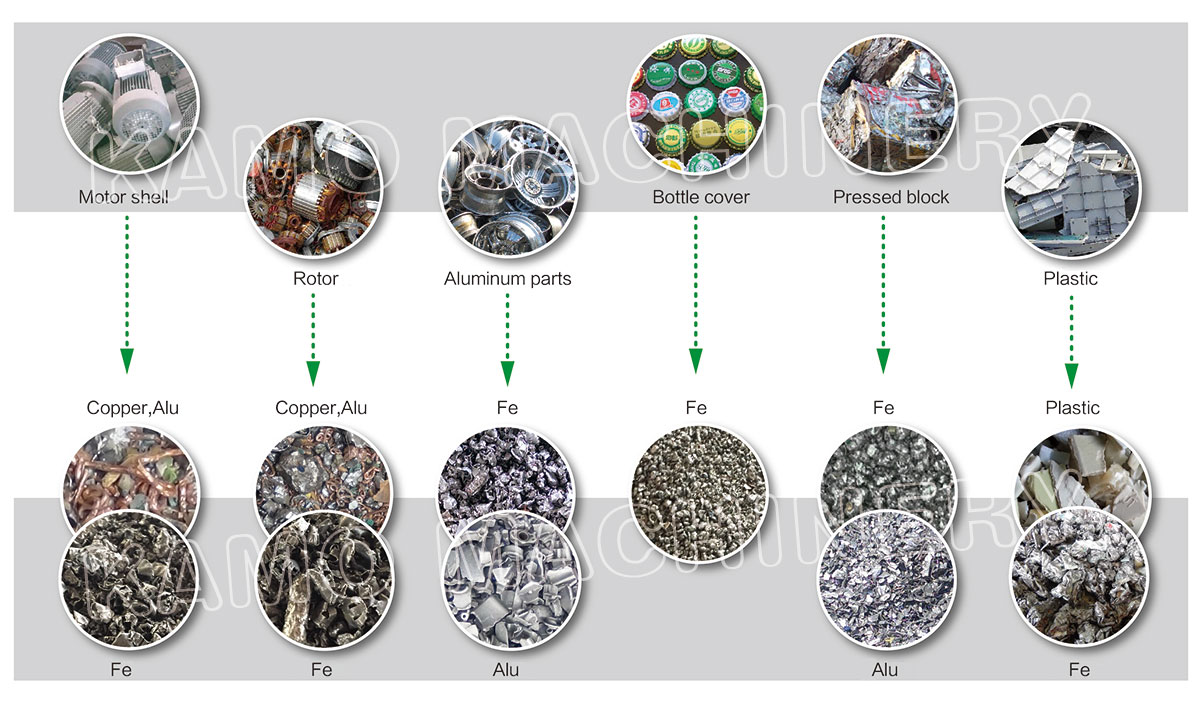

APPLICATION

The equipment is widely used in the crushing of electronic waste, beer bottle caps, computer hard drives, rotors and other materials.

TECHNICAL PARAMETERS

| Model | Rotor diameter(mm) | Feed Size(mm) | The particle size(mm) | Processing capacity(t/h) | Power(kw) | Dimensions(L×W×H)(mm) |

| PCL1000 | 1000 | 270×380 | ≤100 | 10-30 | 55-75 | 2700×1160×2000 |

Product usage

Mainly used for processing high hardness, irregular material from small to medium size. This hammer mill commonly used in non-ferrous metal recy-cling industry and proven higher efficiency compare with others equipment.Output size can be adjusted freely without limited of hammer and lining board.No integrated sieve bars assure defective material fall down easily without damage to machine.