This series single shaft shredder use siemens programmable control system which can control automatically. Equopped with start, stop, reversion and overload automatic reverse function. Also has low speed, high torque, low noise and others features. It is suitable for small materials, such as: plastic head, PET bottle, hard cardboard, Circuit board, plastic barrel,wood. Available to customize special blade roll based on different requirement.

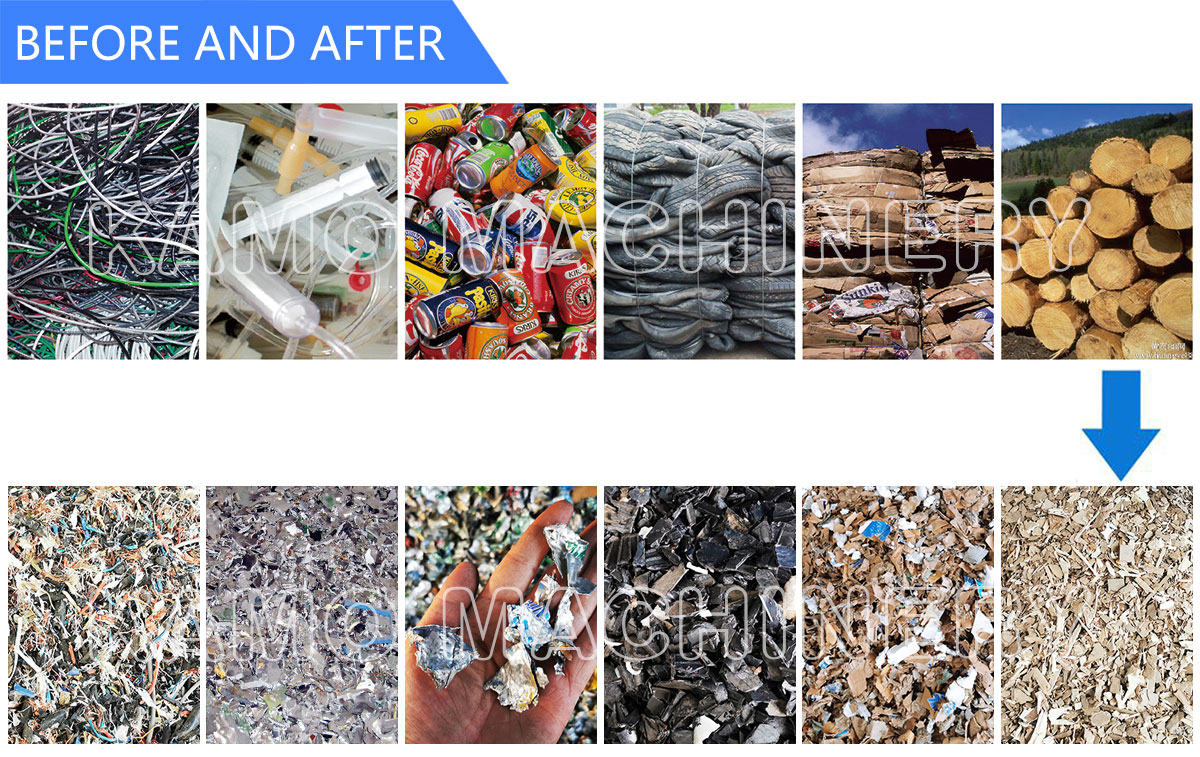

APPLICATION

Plastics-general plastics in the fields of injection molding, extrusion, blown film, etc.

Timber-wooden pallets, logs, wood trim, etc.

Paper-document paper, wrapping paper, cardboard, etc.

Cables-copper core, aluminum core cables and composite cables

Aluminum-cans, aluminum scraps, etc.

Chemical Fiber-Carpet, Labor Insurance, etc.

Sponge-industrial waste

Composite materials-fiberglass products, car windshields, sealing strips, etc.

Destruction-Imitations (counterfeit), substandard products, expired items, etc.

TECHNICAL PARAMETERS

| Model | TL2250 | TL2260 | TL3060 | TL3080 |

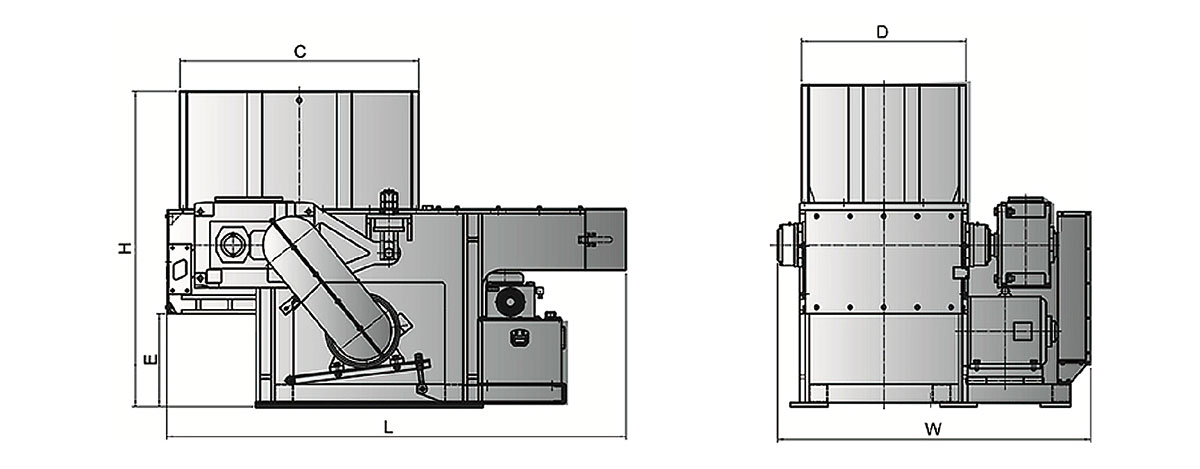

| Dimension(L/W/H)(mm) | 1780×1190×1754 | 1780×1350×1754 | 2455×1478×1700 | 2455×1678×1700 |

| Crushing chamber size(mm) | 857×502 | 857×602 | 1200×600 | 1200×800 |

| Discharging port height(mm) | 546 | 546 | 500 | 500 |

| Cylinder stroke(mm) | 500 | 500 | 750 | 750 |

| Blade turning diameter(mm) | φ224.7 | φ224.7 | φ300 | φ300 |

| Main shaft speed(r/min) | 83 | 83 | 83 | 83 |

| Screen size(mm) | φ25 | φ25 | φ40 | φ40 |

| Rotor blade quantity(pcs) | 24+4 | 28+4 | 30+4 | 42+4 |

| Stator blade quantity(pcs) | 2+2 | 2+2 | 2 | 2 |

| Main power(kw) | 15 | 18.5 | 22 | 30 |

| Hydraulic motor power(kw) | 2.2 | 2.2 | 2.2 | 2.2 |

WORKING PRINCIPLE

The material enters the case from the feed hopper, and the pushing box pushes the material to the rotating knife roller under the push of the hydraulic cylinder. The rotating movable knife and the fixed knife crush the material. The broken material falls through the screen and then is conveyed through the auxiliary conveying equipment Go to the next process or collect and package. The material enters the inside of the shredding box through the feeding system. The box carries the shredding blade. The pushing box pushes the material to the vicinity of the blade. The material is shredded, squeezed, and sheared by the shredding blade. Small pieces of material are discharged from the mesh holes.

PRODUCT ADVANTAGES

1.The blade is made of cold-working die steel. The blade has good strength, high toughness and high cutting performance. The blade has four cutting edges, which can be rotated 90° after wear and continue to be used.

2.The external bearing design can be waterproof and dustproof and prolong the service life of the bearing.

3.Hydraulic forced feeding, the speed is stable and adjustable, and the propulsive force is large and uniform.

4.Hardened gear reducer, high transmission efficiency, strong bearing capacity and low noise.